The Importance of Ballistic Resistant Testing: Certified NVLAP-Accredited Laboratories vs. In-house/Backyard Ranges

Jul 31, 2023

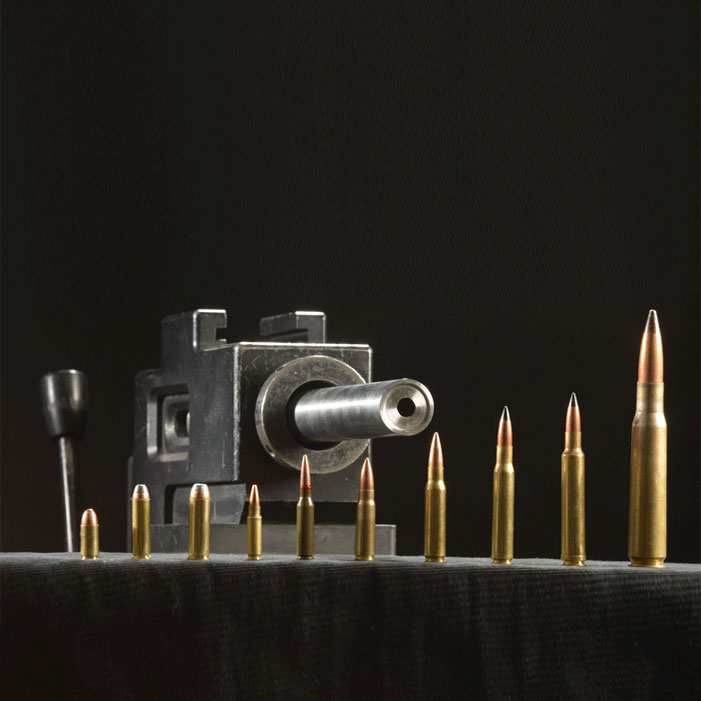

When it comes to ballistic-resistant testing, quality assurance, precision, and consistency are of paramount importance. The product testing environment is critical in ensuring that ballistic-resistant products meet or exceed industry standards, providing the utmost safety and security for the end users.

Should this testing be left to the whims of private companies' in-house facilities or makeshift backyard ranges for such a critical product category? Or should it be entrusted to certified NVLAP (National Voluntary Laboratory Accreditation Program)-accredited laboratories? This post delves into the two divergent paths of testing, analyzing the credibility, reliability, and authenticity of results produced in each environment.

NVLAP-Accredited Laboratories: Unwavering Quality Assurance

Accredited by the National Institute of Standards and Technology (NIST), NVLAP-accredited labs follow a stringent set of protocols, maintain a specific environment, and utilize sophisticated technologies to ensure every test's precision and consistency. They adhere to the highest quality assurance standards, ensuring that ballistic-resistant products are meticulously evaluated for performance, durability, and safety.

These labs uphold their testing credentials through regular audits, continued professional development, and the consistent application of globally recognized testing protocols. As a result, the data produced in these laboratories is considered reliable. The products tested in these environments are validated against a range of established criteria, providing peace of mind to manufacturers and consumers alike about the product's quality and performance under extreme conditions.

Private In-house or Makeshift Backyard Testing Ranges: The Reality

While a private company's in-house or makeshift backyard range might seem like a viable option for ballistic-resistant testing, the lack of rigorous controls and standardized testing conditions can significantly impact the reliability and accuracy of the results. These environments must often be equipped to replicate the extreme conditions under which ballistic-resistant products are expected to perform, leading to quality discrepancies and potential safety risks.

The reliance on self-declared quality or lot testing without standardized controls and monitoring mechanisms can result in inconsistency and variability in product performance. In addition, there's the potential risk of confirmation bias, where test results might be unintentionally skewed to meet the desired outcomes, leading to false positives.

The lack of third-party validation and the potential for compromising the accuracy and reliability of testing procedures due to cost or other factors further undermines the credibility of these testing environments.

Making the Right Choice

In the realm of ballistic-resistant product testing, the stakes are incredibly high. A slight compromise in product quality or performance could result in catastrophic consequences. Therefore, testing in a controlled, standardized environment such as a certified NVLAP-accredited lab is crucial. It ensures product reliability and performance and upholds consumers' trust and confidence in these products.

Choosing to test in NVLAP-accredited labs signifies a commitment to quality, integrity, and the highest levels of safety. Conversely, reliance on private in-house or makeshift backyard ranges for testing can compromise these values, leaving room for inconsistencies and potentially jeopardizing user safety.

Ultimately, choosing between a certified NVLAP-accredited laboratory and a private company's in-house or makeshift backyard range hinges on priorities: the unwavering commitment to safety, quality, and reliability versus the potential for cost-cutting and shortcuts. The decision will shape not just the quality of the products but also the manufacturer's reputation and the end-users safety.

At CAG, we prioritize your safety and quality assurance above all else. Our commitment to these principles is reflected in our rigorous processes for testing body armor and ballistic-resistant materials. We exclusively partner with independent third-party NVLAP-accredited laboratories approved by the National Institute of Justice (NIJ).

This uncompromising approach ensures that all our products meet and often exceed industry standards, providing the highest levels of safety and reliability. We steadfastly believe that your trust in us is directly linked to our relentless dedication to ensuring the exceptional quality of our products.

Only settle for more if you're looking for ballistic-resistant products you can trust. Choose CAG, where safety and quality are not just words but integral parts of our mission.

For more information about our testing procedures or to explore our range of ballistic-resistant products, please feel free to contact our team today. Remember, your safety is our ultimate goal, and we strive to provide you with the best in the industry.

← Older Post Newer Post →