Innovative Weaving Techniques in Ballistic Fabric Manufacturing

Apr 08, 2024

The backbone of effective body armor lies not just in the materials used but in the innovative techniques applied to weave these materials into fabrics capable of stopping bullets and mitigating trauma. As the demand for lighter, more flexible, and more muscular body armor increases, the industry has turned to cutting-edge weaving technologies to enhance ballistic performance and durability. This article explores the forefront of weaving techniques in ballistic fabric manufacturing, highlighting how these advancements set new personal protection standards.

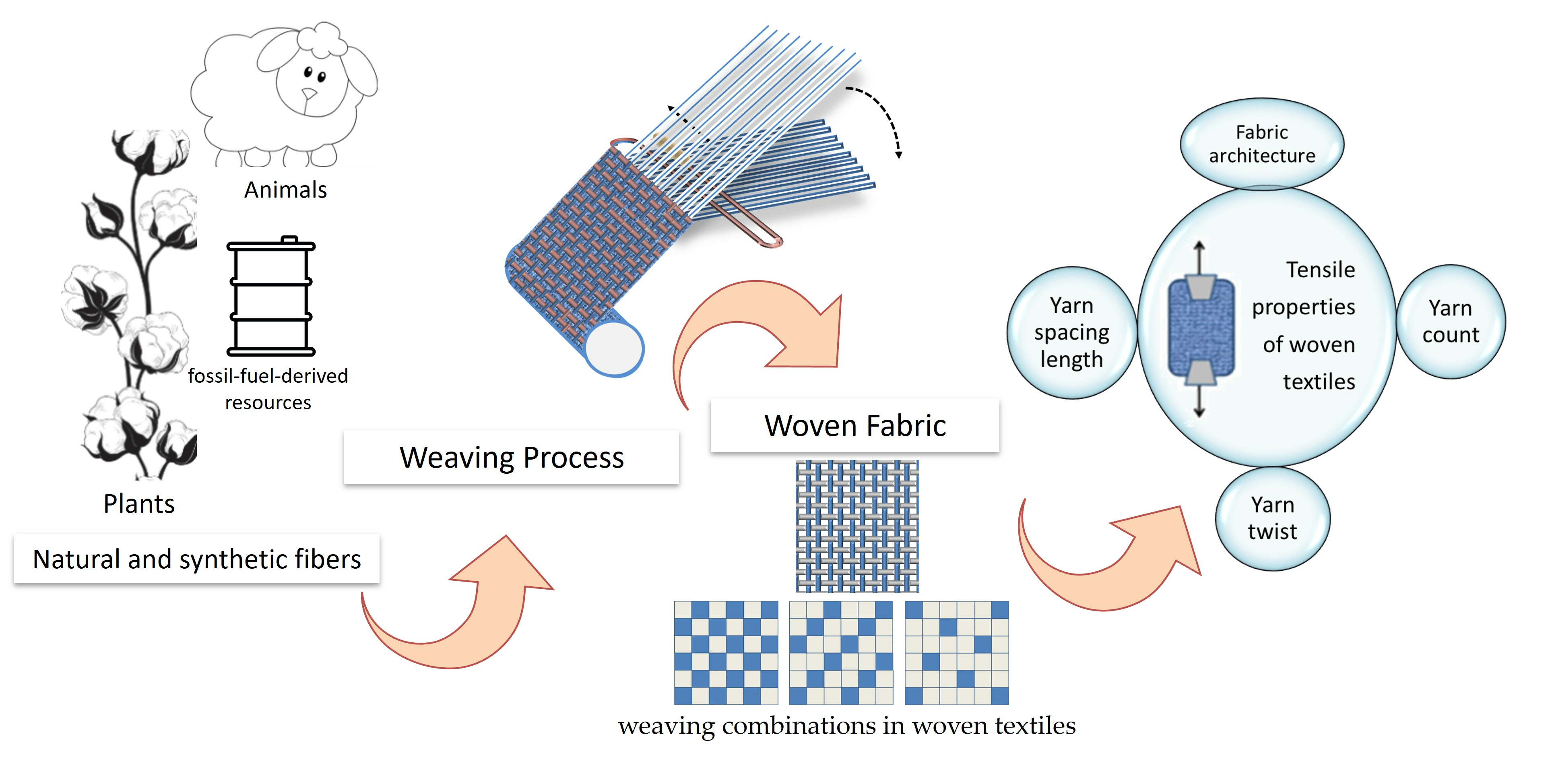

The Evolution of Weaving Techniques

Traditional weaving methods have provided the basis for ballistic fabric manufacturing for decades. However, the limitations of these techniques in meeting the evolving demands of law enforcement, military, and private security markets have driven the quest for innovation. Today, advanced weaving technologies offer improved ballistic resistance and ensure that body armor can withstand the wear and tear of rigorous use.

- 3D Weaving

One of the most significant advancements is the development of 3D weaving technology. Unlike conventional 2D fabrics, 3D woven fabrics are produced in a single piece, eliminating the need for seams or joints that can be potential weak points. This technology allows for integrating multiple layers and types of fibers, creating a unified structure that offers superior ballistic protection and enhanced durability.

- Multiaxial Weaving

Multiaxial weaving techniques involve laying out fibers in multiple directions rather than the traditional orthogonal (90-degree) orientation. This method increases the fabric's ability to disperse the energy of a ballistic impact, improving its protective capabilities. Multiaxial woven fabrics are particularly effective in resisting high-velocity projectiles and providing stab resistance, making them ideal for high-threat environments.

Advantages of Advanced Weaving Techniques

The introduction of advanced weaving technologies in ballistic fabric manufacturing presents several advantages over traditional methods. These include:

- Enhanced Ballistic Performance: By optimizing the orientation and integration of fibers, advanced weaving techniques can significantly improve the ballistic stopping power of body armor.

- Increased Durability: Fabrics produced using 3D and multiaxial weaving are more resistant to wear, tear, and environmental degradation, extending the lifespan of body armor.

- Improved Comfort and Flexibility: Advanced weaving allows for the production of body armor that is not only protective but also comfortable and flexible, accommodating the wearer's movements without compromising safety.

The Role of Material Science

Advances in material science further amplify the benefits of innovative weaving techniques. High-performance fibers such as Ultra-High-Molecular-Weight Polyethylene (UHMWPE), aramids (including Kevlar), and M5 fibers are engineered to provide unmatched strength-to-weight ratios. When combined with advanced weaving methods, these materials contribute to developing body armor that sets new benchmarks in protective performance.

Challenges and Future Directions

Despite the promising advancements, the adoption of innovative weaving techniques faces challenges. The complexity of producing 3D and multiaxial woven fabrics requires specialized equipment and expertise, leading to higher production costs. Additionally, the industry must balance enhancing ballistic performance and maintaining or improving the wearability of body armor.

Ongoing research and development efforts are focused on overcoming these challenges. Innovations in automated weaving technology and exploring new materials promise to enhance ballistic fabrics' capabilities further. The future of body armor manufacturing lies in the continuous evolution of weaving techniques, pushing the boundaries of what is possible in personal protection.

Custom Armor Group: At the Forefront of Innovation

Custom Armor Group (CAG) is committed to leveraging these innovative weaving techniques to produce our ballistic fabrics. By investing in state-of-the-art manufacturing technologies and collaborating with leading material scientists, CAG aims to provide our clients with body armor that offers unparalleled protection, durability, and comfort.

In a world where the threats faced by law enforcement, military, and security professionals constantly evolve, staying ahead with the latest advancements in body armor technology is crucial. Custom Armor Group invites you to explore our range of advanced ballistic protection solutions, incorporating cutting-edge weaving techniques and materials that define the future of personal protection.

Contact Custom Armor Group today to discover how our innovative body armor solutions can meet your specific needs. Together, we can ensure you are equipped with the best protection available, allowing you to perform your duties confidently and securely.

← Older Post Newer Post →